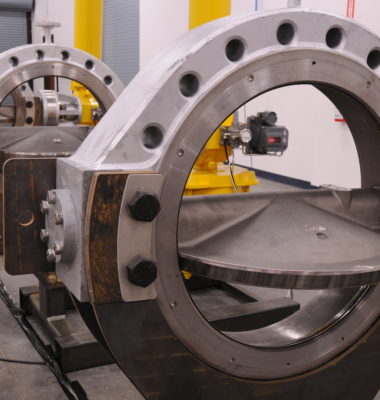

Air-Nitrogen Automated Purge Systems

The auto-ignition of molten sulfur and design of a modified-Claus SRU requires operators prevent excess oxygen from flowing through the unit. Temperature excursions and sulfur fires can be common if excess air enters an SRU.

Using nitrogen for nozzle purges, pre-ignition purge, and thermal reactor nozzle cooling is a simple solution. Nitrogen, however, can be a costly utility. Contact our design team to discuss how an automatic air/nitrogen purge system can minimize your nitrogen consumption.